CNC Milling Cutting Tools and Accessories

CNC milling tools are cutting instruments used in CNC (Computer Numerical Control) milling machines to remove material from a work piece. These tools come in various shapes and sizes, each designed for specific tasks and materials. Here’s a brief description of common CNC milling tools:

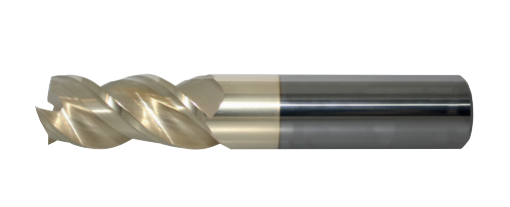

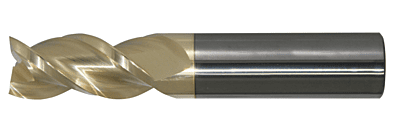

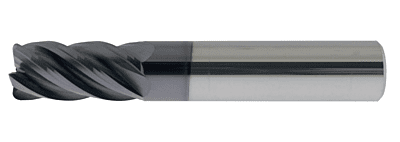

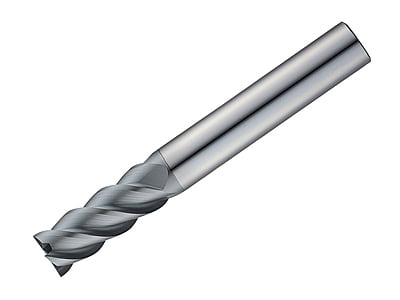

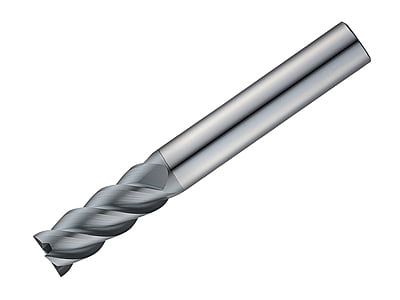

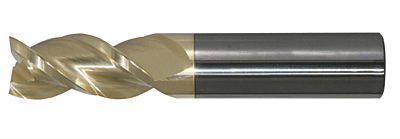

End Mills: The most common type, used for cutting, profiling, and slotting. They come in various geometries like square, ball nose, and corner radius.

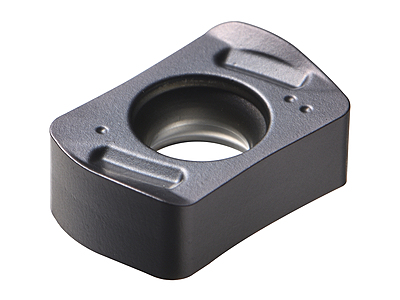

Face Mills: Used for facing operations to create flat surfaces. They have multiple cutting edges and are typically used for large surface areas.

Ball Nose Mills: Feature a rounded tip and are used for 3D contouring and fine detail work, such as in mold making.

Drill Bits: Used for creating holes. They come in various types like twist drills, center drills, and spotting drills.

Reamers: Used to finish holes to precise dimensions and improve surface finish.

Taps: Used for cutting internal threads in pre-drilled holes.

Slab Mills: Used for heavy-duty cutting and large surface areas, typically in horizontal milling machines.

Fly Cutters: Single-point cutting tools used for fine finishing and large surface areas.

Thread Mills: Used for milling threads, both internal and external.

Chamfer Mills: Used for creating beveled edges or chamfers on workpieces.

Dovetail Cutters: Specialized tools for cutting dovetail slots.

Keyseat Cutters: Used for cutting keyways and slots.